VNCPC participated in a workshop to introduce guidelines on ecological industrial zones

On December 21, in Ho Chi Minh City, the International Finance Corporation (IFC) and the Ministry of Planning and Investment (MPI) jointly organized a workshop to introduce technical guidelines: Implementation of Ecological industrial zones.

The workshop attracted the participation of 40 delegates from industrial parks and related units. Especially the presence and speech at the opening ceremony of Mr. Navneet Chadha, Head of IFC’s Asia-Pacific Resource Efficiency Division, Ms. Vuong Minh Hieu – Representative of Economic Zone Management (Ministry of Planning and Investment).

Ms. Vuong Minh Hieu – Representative of Economic Zone Management Department (Ministry of Planning and Investment)

Ecological industrial zone: inevitable trend

By the end of 2017, Vietnam had 326 industrial parks (IPs), industrial parks played an important role in attracting foreign investment, export growth, contributing to GDP and creating jobs.

But industrial parks also consume resources and generate a lot of waste, causing negative impacts on the environment and the community. The ecological industrial zone is increasingly recognized as an effective tool to help the industrial park develop sustainably.

Ms. Vu Tuong Anh – Representative of International Finance Corporaton (IFC)

In essence, ecological industrial zone are IPs in which the community of manufacturing enterprises and infrastructure service providers interact with each other on efficient use of resources, creating an industrial symbiosis network to minimize generate waste to increase economic, environmental and social efficiency for the whole community.

Three basic elements of IPs include: environmental management; resource efficiency, cleaner production in each enterprise in the IPs and industrial symbiosis networks between enterprises and green infrastructure of the IPs. The ecological industrial zone model has been successfully implemented in many countries such as China, Korea, Japan, America, Australia and many European countries.

Industrial symbiosis in ecological industrial zone “key” of sustainable development

Recently, the Government Decree 82/2018/ND-CP issued on May 22, 2018 on the Management of Industrial Zones and Economic Zones, clearly stating the objectives of developing ecological industrial parks and incentive policies. development of industrial zones and criteria for determining IPs in Vietnam. The implementation of IPs in the direction of IPs will contribute to the implementation of Vietnam’s Green Growth Strategy.

IFC has cooperated with the Ministry of Planning and Investment to study and develop technical guidelines on IPs in order to provide the necessary criteria and steps for industrial parks in Vietnam to become IPs.

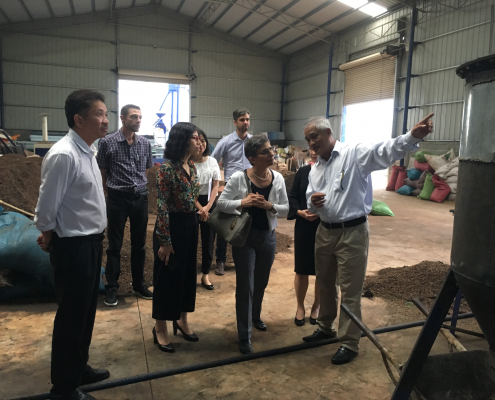

Mr. Le Xuan Thinh – Director of Vietnam Cleaner Production Center Co.Ltd (VNCPC) presented at the workshop.

This technical guide also shows ecological opportunities and solutions for industrial parks in Vietnam. Opportunities for waste symbiosis, recycling recycling are an environmentally effective solution, while creating new business opportunities.

Specifically, an industrial zone that recycles waste water for use in production can reduce up to 40% of that industrial wastewater discharged into the environment, as well as reduce input water costs.

Similarly, the opportunity to recover waste heat to produce hot water and steam for factories in the industrial park has the potential to reduce the use of 20-40% of fuel in an industrial park. The solution of industrial symbiosis in IPs is also one of the tools to practice “economic circulation” for sustainable development.

VNCPC