Full name of the project:”Introduction of Best Available Technique (BAT) and Best Environmental Practices (BEP) methodology to demonstrate reduction or elimination of Unintentionally produced Persistent Organic Pollutants (U-POPs) releases from the industry in Vietnam”

Donors: Global Environmental Fund (GEF) with the United Nations Industrial Development Organization (UNIDO)

Implementing agency: the Industrial Safety Techniques and Environmental Agency (ISEA) – Ministry of Industry and Trade (MoIT) of Vietnam.

Technical partners: Vietnam Cleaner Production Centre (VNCPC) and Dioxin Laboratory

Implementation duration: Jul/2010 – Jul/2011

Objectives of the project

Overall objective: To establish the required human resources and infrastructure to implement the obligations of the Stockholm Convention in Article 5 “Measures to reduce and eliminate releases from unintentional production” and coordinate its activities with the national strategies on environmental protection, industrial and sustainable development and cleaner production.

Specific objectives:

- According to the Action Plan, applying BAT and promote BEP in new sources in priority (Part II of Annex C of the Stockholm Convention) source categories by 16 May 2008, and complete dioxin release reduction demonstrations in selected existing sources in the priority sectors by 2010. The sector-wide introduction of BAT/BEP is planned to be completed by 2020.

- Support BAT/BEP projects and define new sources of U-POPs relating to building capacity of monitoring and research on POPs.

Implementation activities and Results

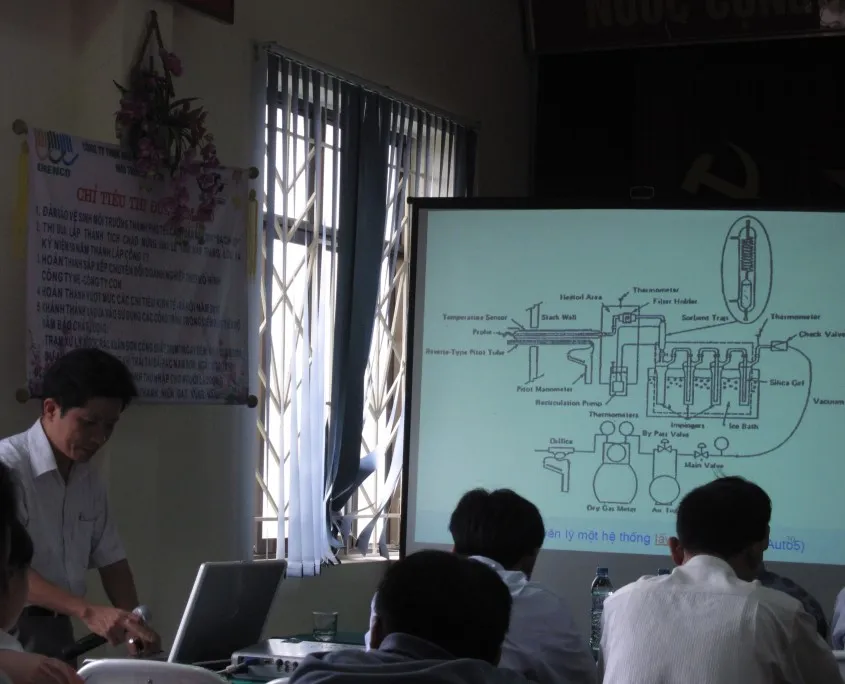

- Training courses on “Introduction of BAT/BEP and Monitoring U-POPs in the Vietnamese industry”

- Compiling 04 technical books on “Introduction of BAT/BEP methodology to reduce the emission of Persistent Organic Pollutants” for 04 selected industry sectors: Metallurgy, Pulp and Paper, Incinerator and Cement Production

- Assessment of RE-CP, BAT/BEP at participating enterprises.

- Introducing local consultants and reports to ISEA and VEA; and coordinating with local and international experts in implementing the project:

- Associate, Prof. Tuong Thi Hoi – Expert on Cement and Incinerator.

- M. Tech. Chu Duc Khai – Expert on Metallurgy.

- Dr. Dang Van Son – Expert on Pulp and Paper productionTS. Đặng Văn Sơn – Chuyên gia ngành sản xuất Giấy và Bột giấy.

- Dr. Kåre Helge Karstensen – International expert on Incinerator

- Dr. Pasquale Spezzan – International expert on Metallurgy.

- Experts and consultants on RE-CP from VNCPC

- Selected enterprises as:

- Luu Xa Steel Factory – Thai Nguyen Iron and Steel Joint Stock Corporation – Metallurgy industry.

- URENCO Bac Son – Hanoi Urban Environment One Member Limited Company (URENCO) – Waste treatment technology (Incinerators)

- Bai Bang Paper Company – Vietnam Paper Coorperation – Pulp and Paper industry sector

- Holcim Vietnam Company – Cement industry sector